The importance of accurate portioning in sausage production

Sausage production is one of the most demanding processes in the meat industry. The challenge is not only to standardize the final product in terms of weight and size, but above all to preserve the quality of the meat mass during stuffing. One of the most common problems producers face is the stress placed on the raw material: when the meat mass undergoes excessive pressure or friction, its protein structure is damaged, the texture deteriorates, and its ability to retain water and fat decreases. The result is sausages with reduced consistency, less appealing appearance, and ultimately lower commercial value.

Therefore, the need for accurate portioning combined with gentle handling of the meat mass is fundamental. In a market where consistency and quality define a company’s reputation, producers seek solutions that do not compromise productivity for quality.

Rotor technology and Risco’s different approach

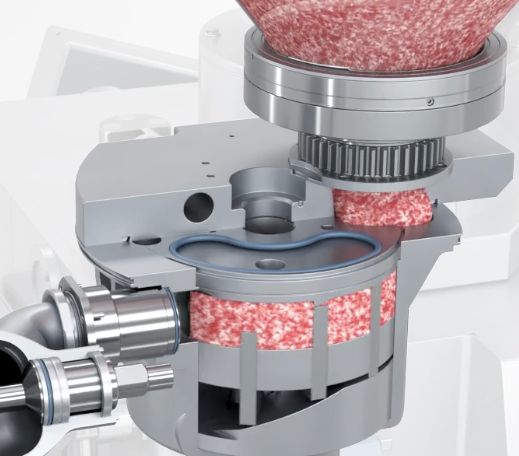

This is where rotor-based stuffing technology comes into play. Unlike traditional screw or vane pumps, the Risco rotor works with a dosing chamber that fills and empties with absolute precision. Its operating principle allows the mass to be conveyed gently, minimizing mechanical stress. In this way, the protein network is preserved, muscle fibers are not cut, and friction-induced temperature rise is avoided.

The outcome of this technology is twofold: on the one hand, uniformity in the weight of each sausage is ensured, which reduces waste and facilitates quality control. On the other hand, the meat mass remains “alive,” maintaining proper water and fat binding – something clearly reflected in both the taste and appearance of the final product.

Why major producers choose this solution

It is no coincidence that the largest sausage and deli meat manufacturers in Italy have adopted this technology. In a country with a deep tradition in charcuterie and strict expectations for flavor and presentation, quality is paramount. These companies have found that rotor stuffing machines guarantee product stability, reduced weight variation, and improved texture – all factors that ultimately set their sausages apart in the marketplace.

Their experience shows that choosing the right production technology is not just about machinery, but a strategic decision that directly affects a company’s competitiveness.

Accurate portioning and careful handling of the meat mass are critical factors in producing high-quality sausages. Rotor technology, as implemented in modern stuffing machines such as those by Risco, offers a comprehensive solution that combines precision, product quality, and efficiency. For producers aiming at premium products while reducing losses, this approach has become the clear path forward.

The special rotor of Risco allows accurate portioning while at the same time preventing stress on the product. The product moves steadily, on a single plane, without being compressed.